I. Industry Turmoil Under Policy Storm

In 2021, the EU’s Single-Use Plastics Directive came into effect, explicitly banning traditional PE/PP packaging materials from the market. This policy sent shockwaves through the European apparel supply chain—one German apparel importer faced a triple crisis:

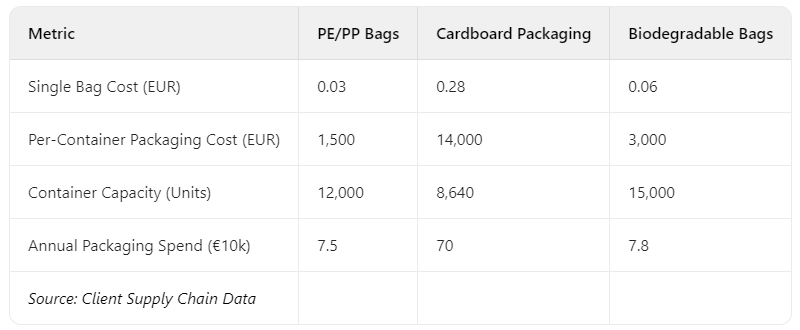

• Compliance Risk: Their existing PE/PP self-sealing bags were listed as prohibited, with potential fines of up to €500,000 for continued use

• Cost Surge: Switching to traditional cardboard packaging increased procurement costs by 320% year-on-year, adding €12,000 in packaging costs per container

• Logistics Bottleneck: The bulky nature of paper packaging expanded volume by 40%, reducing container loading capacity by 28% and increasing annual freight costs by €230,000

II. The Solution: Biodegradable Bags as a Value Driver

Amid these challenges, the importer discovered a transformative solution in biodegradable compostable self-sealing bags:

(1) Material Innovation: From Pollution to Sustainability

Crafted from PLA+PBAT composite material certified to EN 13432, these bags fully decompose into CO₂, water, and organic matter within 180 days under industrial composting conditions—leaving heavy metal residues below 0.1ppm. This not only meets the EU’s strict PPWR regulations but also secures the Nordic Swan Ecolabel, opening doors to premium retail channels.

(2) Cost Efficiency: An 89% Procurement Cost Reduction

(3) Logistical Advantages: Space-Saving Drives Efficiency

At just 0.02mm thick, these bags reduce packaging volume by 65% compared to cardboard, delivering tangible benefits:

Carbon Compliance: A 42% reduction in transport-related carbon emissions aligned with the EU’s CBAM carbon tariff requirements.

Shipping Efficiency: Container capacity increased from 8,640 to 15,000 units, cutting annual 40-foot container usage by 4.

Warehouse Savings: A 38% improvement in storage efficiency saved €170,000 annually in warehousing costs.

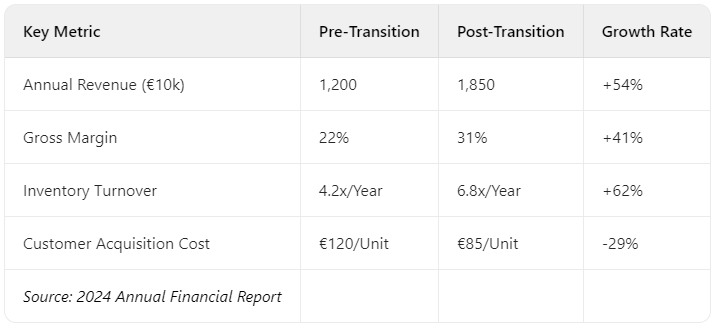

III. Market Impact: From Cost Saver to Profit Accelerator

(1) Competitive Edge in Retail

- Pricing Power: The 89% cost reduction enabled a 12% price cut, boosting sales by 37% on platforms like Zalando.

- Brand Enhancement: A “Climate Neutral” certification drove a 25% premium on luxury lines and an 18% rise in customer retention.

- New Opportunities: Eco-friendly packaging qualified the importer for H&M’s sustainable product network, expanding market reach.

(2) Financial Performance Improvements

IV. Industry Lessons: The Ripple Effects of Sustainable Packaging

(1) Technological Leadership

Incorporating nano-calcium carbonate additives increased the bags’ tensile strength to 58MPa—30% stronger than traditional PE—reducing transit damage from 6.3% (cardboard) to 1.2%.

(2) Supply Chain Collaboration

A joint traceability system with SGS provided end-to-end transparency—from corn cultivation to packaging—earning the German Blue Angel certification and entry into Metro’s sustainable procurement program.

(3) Regulatory Compliance & Incentives

EN 13432 certification and circular design secured €98,000 in EU Green Transition Fund subsidies while lowering waste disposal costs from €85/ton to €12/ton under the German Packaging Act.

V. Future Outlook: Scaling Sustainability

For 2025, the importer plans to expand biodegradable solutions across:

- E-Commerce: Developing certified courier bags for Amazon’s Climate Pledge Friendly program.

- In-Store Experience: Launching compostable garment covers paired with in-store recycling stations.

- Financial Innovation: Partnering with banks to offer “Green Packaging Loans” for sustainable supply chain upgrades.

This case demonstrates how regulatory pressure can catalyze innovation. Biodegradable compostable self-sealing bags have evolved from a compliance necessity into a strategic asset—delivering cost savings, operational efficiency, and brand value. As the industry shifts toward sustainability, such solutions are not just optional but essential for long-term competitiveness.